DuraSense

Lubrication condition monitoring and requirement-based lubrication

Your benefit:

- Machine availability is increased by reducing the number of unplanned downtimes

- Planning is made easier, which reduces maintenance costs

- Production supply costs are reduced

Comprehensive reasons to use DuraSense

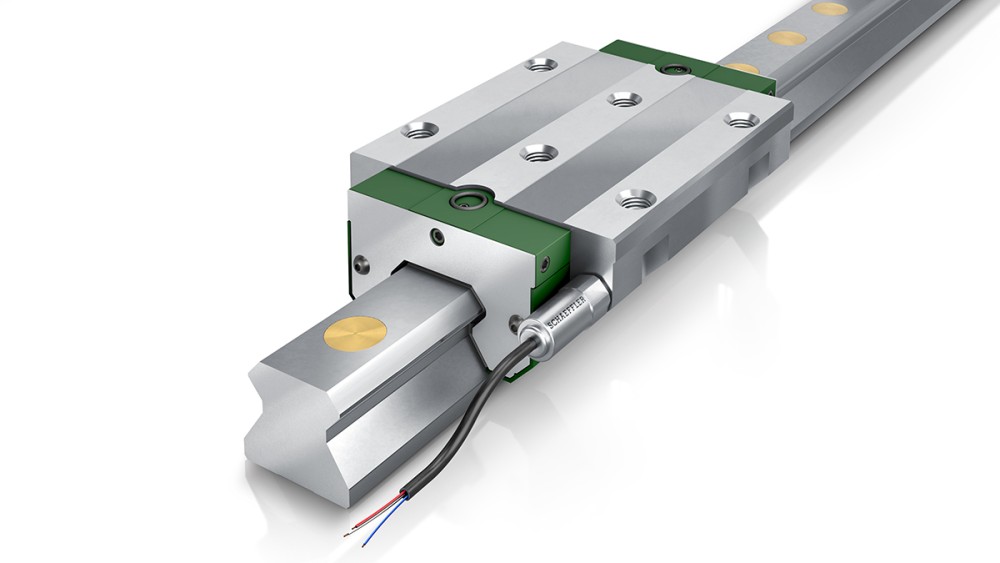

DuraSense monitors lubrication conditions in linear guidance systems and triggers the signal for a relubricating impulse from a relubrication unit when, for example, insufficient lubrication occurs

DuraSense ensures that the lubricating impulse also reaches the carriage. If this is not the case (e.g. due to a loose or blocked lubricant supply line), DuraSense triggers the corresponding signal.

Up to 30% less lubricant consumption

Features

- One sensor element per carriage

- Sensor element on the end face of the carriage; PPU (pre-processing unit) in a stable aluminum housing

- PPU with connections for up to seven sensors, as well as Ethernet, field bus, and SPS connections

- Connection to the Schaeffler Smart EcoSystem will be possible in the future